|

|

|||||

|

April 2015 • Vol. 4, Issue 2 |

|||||

|

H New Jersey Magnet Incident Illustrates Cryostat Based Hazards

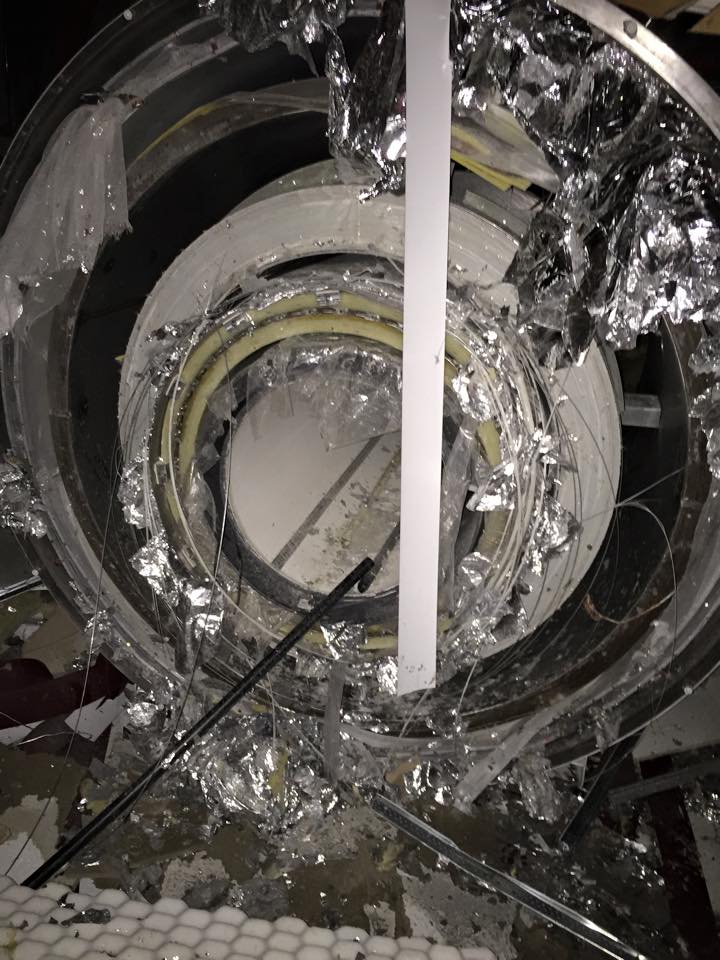

In March this year, on line news outlets covered an “explosion” in an MRI machine being decommissioned at an animal hospital in New Jersey USA. Amongst the images of animals being evacuated, were a few images of scattered debris and collapsed ceilings in the rooms around the MR magnet that illustrated the potential explosive power of the expansion from liquid Helium to gas when trapped inside a cryostat. The event critically injured one worker decommissioning the system. Two other contractors were in the room preparing for a new magnet to be installed. The incident is currently being investigated by OSHA, the U.S. Federal occupational safety and health administration, but while respecting that investigation, and the privacy of the injured workers this piece will lay out the events and potential lessons as they appear from public domain sources. The “explosion” was not flammable, it was the result of boiling liquid helium somehow trapped in the magnet container, the cryostat. Liquid Helium expands 760:1 when it goes from liquid to gaseous form and continues to expand rapidly as it rises in temperature, therefore in a sealed container pressures can get extreme and rupture the cryostat. This force can be seen in another news report from 2006, available on YouTube https://www.youtube.com/watch?v=1R7KsfosV-o In the New Jersey event the pressure blew off the bolted endcaps of the cryostat, sending them through several internal walls of the building and lifting ceiling sections. The magnet was being decommissioned and scrapped, and therefore needed to be warmed up de pressurised and perhaps partially disassembled. It is thought that the magnet was quenched three days earlier, and that the system was left without magnetic field to allow any remaining helium to boil off. It is possible that the cryostat developed a negative pressure gradient because of the liquid helium inside and sucked air in to the system. The water and air would freeze potentially blocking cryostat. On the day of the event it seems the service engineer breached the vacuum space, in preparation for opening and disassembling the magnet. He would have assumed the liquid helium had evaporated, but when the vacuum was released the magnet exploded. MR service engineers in LinkedIn groups believe this indicates that there was a substantial amount of liquid helium remaining and that the cryostat was sealed. Most service engineers typically do a ramp down of the system instead of actually quenching the magnet. Images from the scene show a 1000 pound (≈ 500 kg) inner helium tank, the large cryostat endplate and a G cylinder all blown through two walls, attesting to the forces involved.The event illustrates the potential forces involved when helium boil off is contained. The 2006 cryostat explosion video is often used in MR safety presentations, but because it occurred outside, on a magnet with welded endcaps, the destructive potential was not as obvious as in the New Jersey event. The

incident attracted a lot of attention on live internet MR forums.

The MRI Safety group page has hosted most of the discussion, with

threads emerging on MRI WORLD, and Certified MR Technologists, as

well as timely updates on the SMRT sponsored

MR Technologist

listserver. More images and opinions of varying qualification can be

found in those discussions. The lessons from these events appear to be:

Images reprinted with permission from a private source.

|

|||||

|

E-Signals is a publication by the International Society for Magnetic Resonance in Medicine for the benefit of the SMRT membership and those individuals and organizations that support the educational programs and professional advancement of the SMRT and its members. This publication is the compilation of the leadership of the SMRT and the contributions of the staff in the ISMRM Central Office. |